Open Hole Services

Density

The high-resolution measurements of the Platform Express system include the Three-Detector Lithology Density (TLD) tool, which is housed in the High-Resolution Mechanical Sonde (HRMS). The TLD measures formation density and formation photoelectric factor. Part of the TLD measurement is called a backscatter density measurement because it uses a third detector located close to the source.

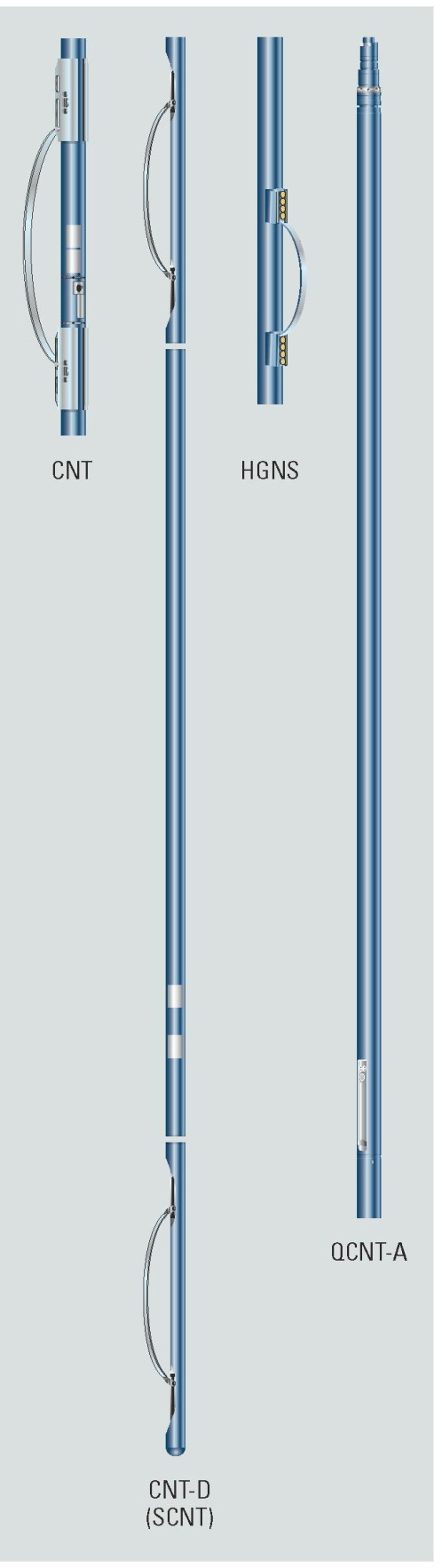

Porosity

The CNL Compensated Neutron Log tool (CNT) contains a radioactive source that bombards the formation with fast neutrons. The neutrons are slowed, primarily by hydrogen atoms in the formation. Detectors count the slowed neutrons deflected back to the tool. Because the CNT responds primarily to the hydrogen content of the formation, the measurements are scaled in porosity units.

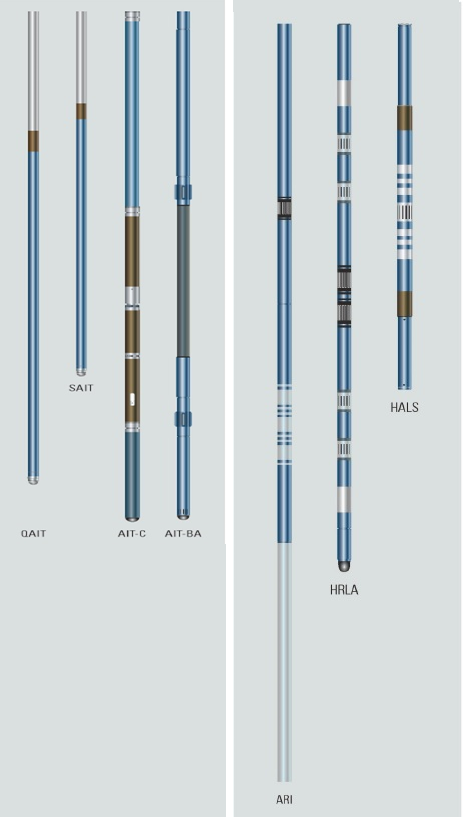

WBM & OBM Resistivity

The HRLA High-Resolution Laterolog Array provides five independent, actively focused, depth- and resolution matched measurements that can resolve the true formation resistivity in thinly bedded and deeply invaded formations. Unprecedented combinability results from the through-wired tool design. The absence of a current return at surface as well as no required use of a bridle greatly improves wellsite efficiency.

Formation Pressure & Sampling

The MDT Modular Reservoir Dynamics Tester measures reservoir pressure quickly and accurately, collects representative fluid samples from multiple layers, and provides permeability and anisotropy data through a variety of interval pressure transient tests. The MDT tool can also be used to conduct a mini-frac test to obtain the minimum in situ horizontal stress in several layers.Live Fluid Analyzer (LFA)

Sonic & Porosity

The DSI Dipole Shear Sonic Imager combines monopole and dipole sonic acquisition capabilities. The transmitter section contains a piezoelectric monopole transmitter and two electrodynamic dipole transmitters perpendicular to each other. An electric pulse at sonic frequencies is applied to the monopole transmitter to excite compressional- and shear-wave propagation in the formation.

Seismic

The VSI* Versatile Seismic Imager uses Q-Technology three-axis single sensor seismic hardware and software and advanced wireline telemetry for efficient data delivery from the borehole to the surface. Each sensor package delivers high fidelity wave fields through the use of three-axis geophone accelerometers, which are acoustically isolated from the main body of the tool. The number of sensors, inter sensor spacing, connection type (either stiff or flexible), and tool diameter are field configurable to ensure the maximum versatility of the array.

Tough Logging Conditions (TLC)

The TLC Tough Logging Conditions system (TLCS) makes it possible to deploy tools for wireline logging in highly deviated or horizontal wells and also in hostile environments and deep wells. Wireline tools are mechanically connected beneath the drill pipe using the Downhole Wet Connector Head (DWCH) and run in to a predetermined latch point.

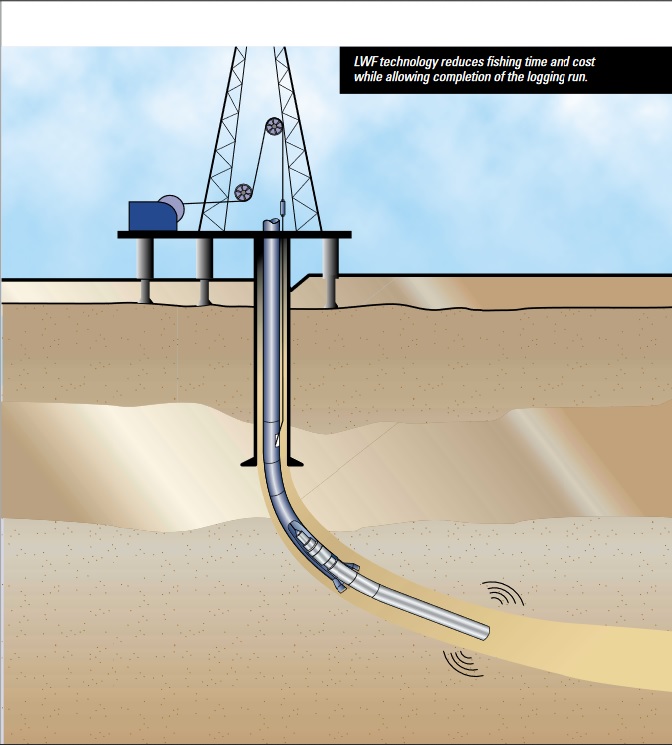

Logging While Fishing (LWF)

LWF logging-while-fishing technology saves time and reduces cost by enabling the resumption of logging operations during fishing. In most cases, the LWF technique eliminates the conditioning trip required before relogging because the fishing job is converted to a drill pipe-assisted log that completes the original descent in the wellbore.

E-Line

Coiled tubing logging (CTL) is used to deploy wireline logging tools in holes where they cannot naturally be deployed on their own. These conditions include deviated wells with significant drag or where descent is not easy. Operations are essentially the same, with the cable permanently connected to the tool string at all time.

WBM (FMI)& OBM (OBMI) Images

The FMI Full bore Formation Micro-Imager provides an electrical borehole image generated from up to 192 micro resistivity measurements. Special focusing circuitry ensures that the measuring currents are forced into the formation, where they modulate in amplitude with the formation conductivities to produce low-frequency signals rich in petro physical and lithological information and a high-resolution component that provides the microscale information used for imaging and dip interpretation.

Magnetic Resonance

The CMR-Plus* Combinable Magnetic Resonance tool with high-logging-speed capability makes nuclear magnetic resonance (NMR) measurements of the buildup and decay of the polarization of hydrogen nuclei (protons) in the liquids contained in the pore space of rock formations. One primary measurement of the CMR-Plus tool is the total formation porosity. Borehole NMR measurement is unaffected by solid materials, so the measurement is not sensitive to matrix type and therefore lithology independent.

Cased Hole Services

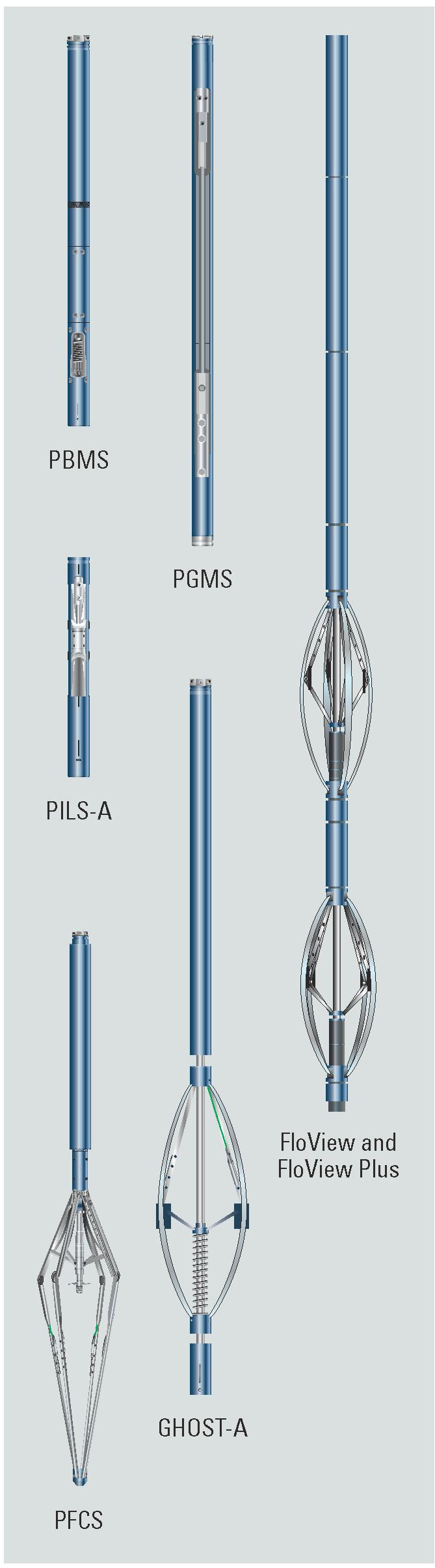

Production Service Platform

The PS Platform integrated production services platform performs in vertical, horizontal, or any angle of borehole deviation to provide three phase flow profiles and production monitoring or diagnostic information. Measurement capability is in both real-time and memory modes. Memory PS Platform service uses many of the same downhole tools and sensors as the PS Platform system to acquire measurements for memory operations. In the PS Platform memory configuration, a memory module and battery replace the internal surface readout telemetry cartridge in the Platform Basic Measurement Sonde (PBMS). The conversion does not increase the length of the tool string, and the flexibility provided by the sensor and tool combinations is maintained regardless of the mode of conveyance.

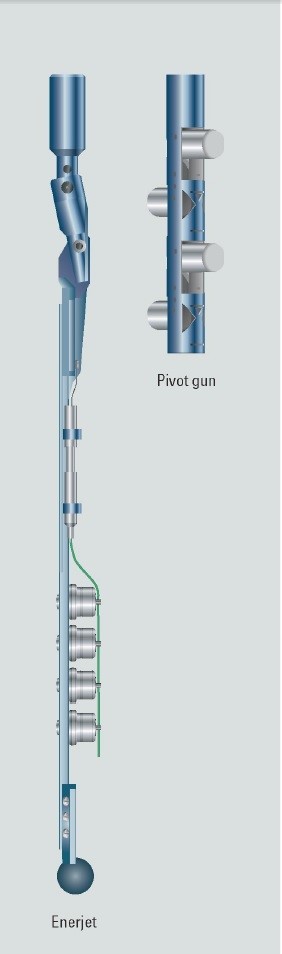

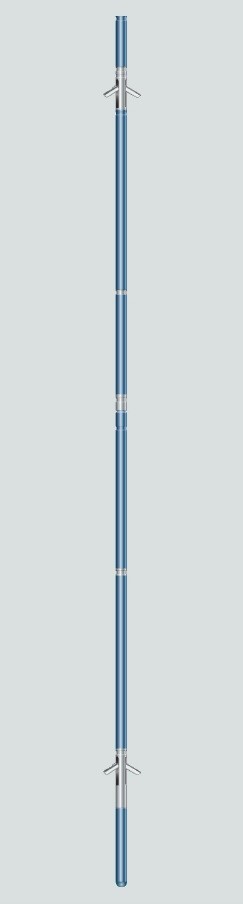

Perforation

Modern perforating technology has evolved from simple holes in the casing to scientific, objective-oriented services adapted to achieve sophisticated and versatile completion designs. Perforating is now used to optimize permanent completions, temporary completions such as DSTs, and workovers. Along with services such as hydraulic fracturing, sand management, extended-reach and horizontal wells, completion fluids engineering, and well testing, perforating has become indispensable for improving productivity. Different type of perforation system are performing such as including but not limited to HSD, Enerjet and punching services with Wireline and TCP methods. Also, perforation system could be designed in advance and interpreted the result with special software by WSI reservoir champion engineers.

Over Balance (CPST) & Under Balance (MPBT) Plug Setting

The Casing Packer Setting Tool (CPST) provides a reliable method of deploying plugs and packers in the wellbore during completion, isolation, or abandonment. The mechanical plug-back tool (MPBT) is used in through-tubing recompletions. Using a mast or a crane, could be used to run MPBT in case of rig less operation which both shall be provided by WSI. Recompletions can be accomplished without the cost of a workover rig. The anchored elastomeric plug is run through tubing and set in casing to plug off fluid flow in the casing below the plug.

Pipe Recovery & Colliding

The FPIT Free-Point Indicator Tool uses a stretch sensor and a torque sensor to accurately determine the free point in stuck drill pipe, drill collars, tubing, or casing.

Cement Evaluation

Cement bond tools measure the bond between the casing and the cement placed in the annulus between the casing and the wellbore.

Casing Evaluation

The UCI* Ultrasonic Corrosion Imager is an evolution of the USI Ultrasonic Imager. The UCI tool provides all the answers required to locate, identify, and quantify casing damage or corrosion. The design is specifically engineered for High-azimuthal-resolution images and detailed examination of both the inner and outer surfaces of casing ranging from 41⁄2 to 133⁄8 in. [11.43 to 33.97 cm]. Combination USIT with CBL-VDL tools is the advantage to have result in one run to save the rig time.

Noise & HPT

To run a logging tool and data processing software which will capture the incoming noise in borehole and decode it into components related to reservoir flow and those emanated from completion elements and possible leaks.

Pressure Equipment (WHE)

Wellhead Pressure control equipment string is designed for complete control of the well pressure during logging operations on the live well which will provide different barrier according to WSI well integrity standard.