DESCRIPTION

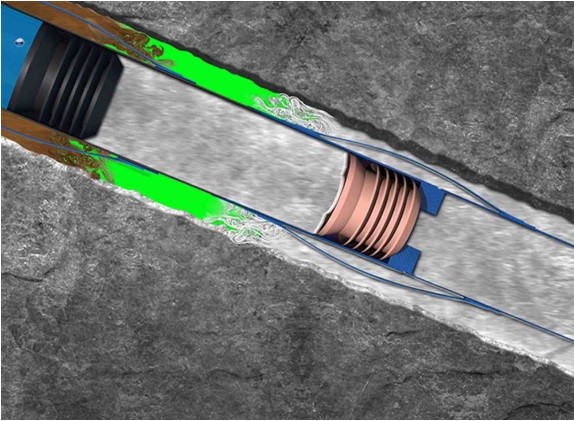

The cement sheath is vital in that it serves to protect and support the casing and deliver the necessary zonal isolation for the life of the well. And while cementing is conventionally viewed as the last step in drilling operations, WSI also designs cementing solutions as the first step in completions. Throughout the life of the well, the cement sheath is required to withstand the cumulative stresses from well events such as pressure testing, well testing and stimulation treatments.

The properties of cement such as viscosity, thickening time, and strength are of prime consideration when engineering for the highest probability of a successful primary cementing operation. The viscosity and thickening time have to be optimized so that the slurry remains pump-able long enough to place the cement across the desired zones and achieve top of cement (TOC). Additionally, the cement should set as quickly as possible after pumping stops and minimize the wait on cement (WOC) time while achieving the necessary structural integrity for retaining zonal isolation integrity throughout the life of the well.

The physio-mechanical properties of the cement need to be optimized for the specific attributes of each well. Each well is unique in regards to pore pressure and fracture gradient, bottom-hole temperature and temperature distribution throughout the well, bottom-hole pressure, physical properties of the formation, properties of fluids already in the wellbore, wellbore deviation, annular space clearance, and many more variables. WSI has a wide range of cementing solutions that can be designed to the demands of each well.