Surface Well Testing

Surface well testing is the only technique available to assess reservoir potential under dynamic conditions. It validates well performance during cleanup and commissioning and provides reservoir monitoring for better field management. This technique can be used to clean the well-bore from scale, debris, or drilling fluids or to separate the well effluent into constituent phases and perform measurements on each phase, using additional equipment including multiphase separators, tanks and pumps.

Data Acquisition Services

The Data gathered during Well Testing period includes volumetric flow rate and pressure observed in the selected well. Outcomes of a well test, for instance flow rate data and gas oil ratio data, may support the well allocation process for an ongoing production phase, while other data about the reservoir capabilities will support reservoir management.

Drill Stem Testing

A drill stem test (DST) is a temporary completion of a wellbore that provides information on whether or not to complete the well. The zone in question is sealed off from the rest of the wellbore by packers, and the formations' pressure and fluids are measured. Data obtained from a DST include the following, fluid samples, reservoir pressure, formation properties including permeability, skin, and productivity estimates, including flow rate and hydrodynamic information.

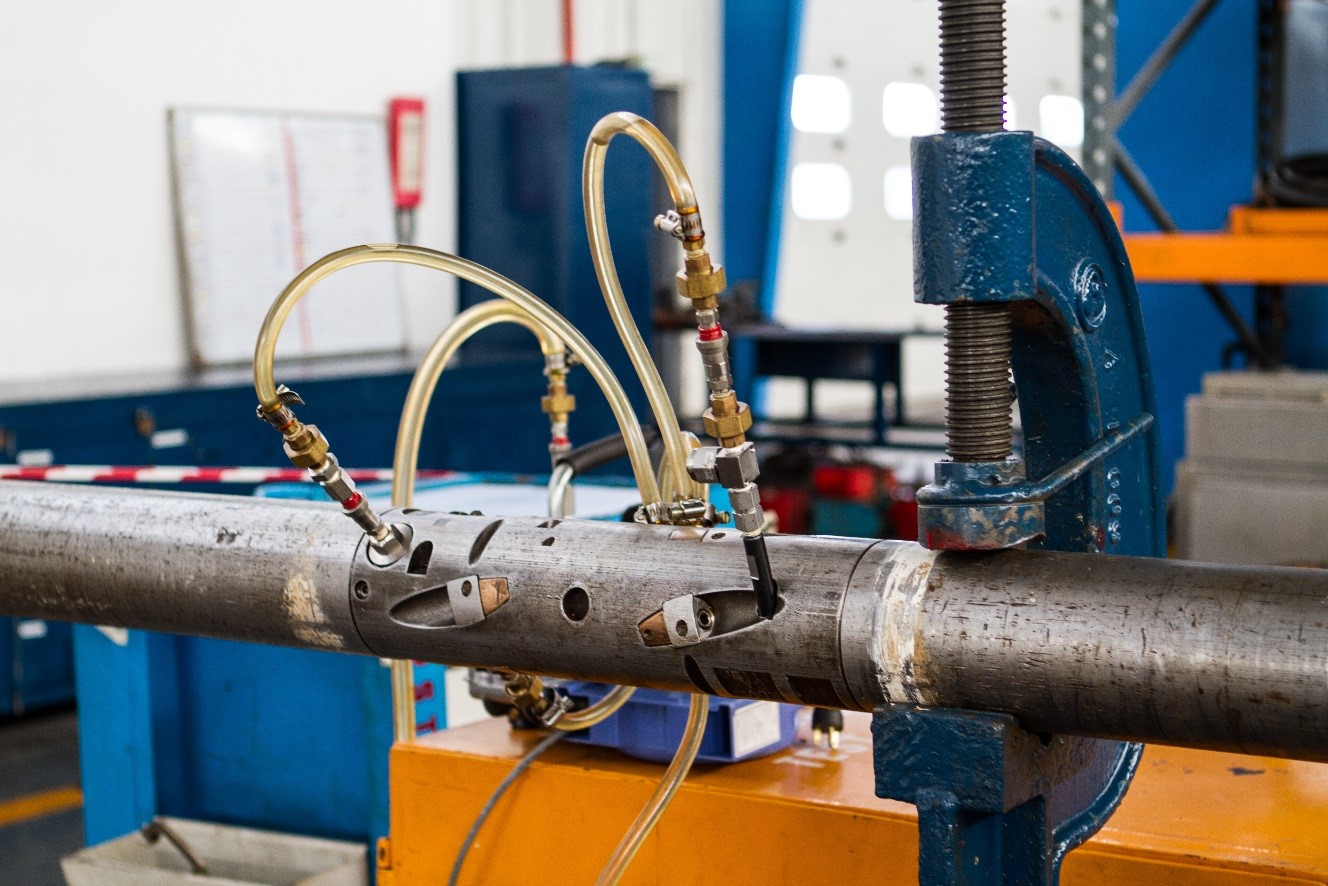

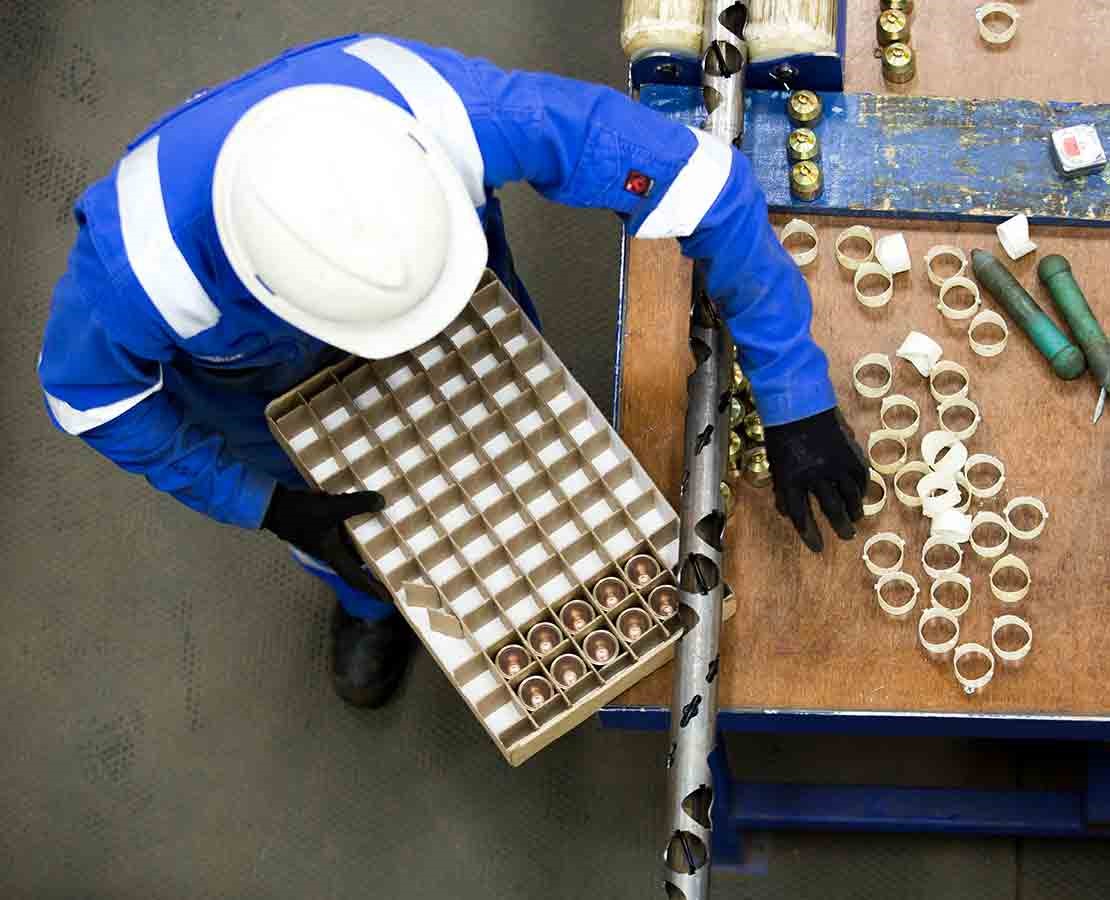

Perforation (TCP, CTP)

Perforation is the process used to establish a flow path between the near reservoir and the wellbore. It normally involves initiating a hole from the wellbore through the casing and any cement sheath into the producing zone. The effectiveness of the perforating process depends on the care and design of the procedure. Because a high percentage of current wells use a cased-hole completion, the importance of the design and application of the perforating process cannot be overstated. Perforations are an elemental piece of the inflow section of the well and have significant impact on the total completion efficiency.

Slickline

A single-strand wireline used to run and retrieve tools and flow-control equipment in oil and gas wells. The single round strand of wire passes through a stuffing box and pressure-control equipment mounted on the wellhead to enable slickline operations to be conducted safely on live wellbores. Slickline operations involve maintenance, such as the removal of wax, scale, sand and fill build-ups, terminating flow and setting hydraulic packers using sealing plugs, gauge cutting, setting or removing plugs, deploying or removing wireline, retrievable valves and memory logging.

Sampling Services

Your laboratory analysis is only as good as the samples recovered. To truly represent the reservoir, formation fluid samples must be collected at reservoir conditions. We deploy pressure-compensating equipment that enables controlled, uncontaminated sampling without flashing, and then maintains those conditions as samples are returned to surface.

Production Services

At production step where the production facilities are not fully operational, a set of well testing equipment is utilized to handle part of production to gain production goals and rate increment until the facilities are completed.